At Masaba, our engineers analyze, calculate, design, and build custom hydraulic systems to fit your specific needs. With more than 25 years of experience and in-house capabilities, we have the expertise necessary to be your full-service provider of engineered design, fabrication, assembly, and testing of hydraulic systems. We provide technical support and superior troubleshooting to solve your problems quickly.

Complete Engineered System Design of Circuits:

- Fixed-delivery open-loop

- Variable-volume pressure-compensated open-loop

- Load-sense pressure-compensated open-loop

- Horsepower-limiting circuits

- Variable-volume closed-loop

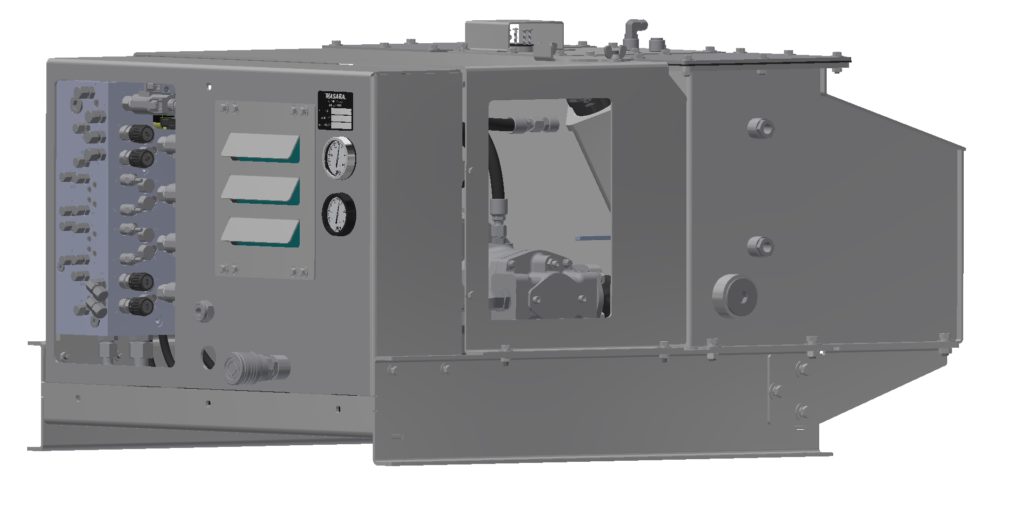

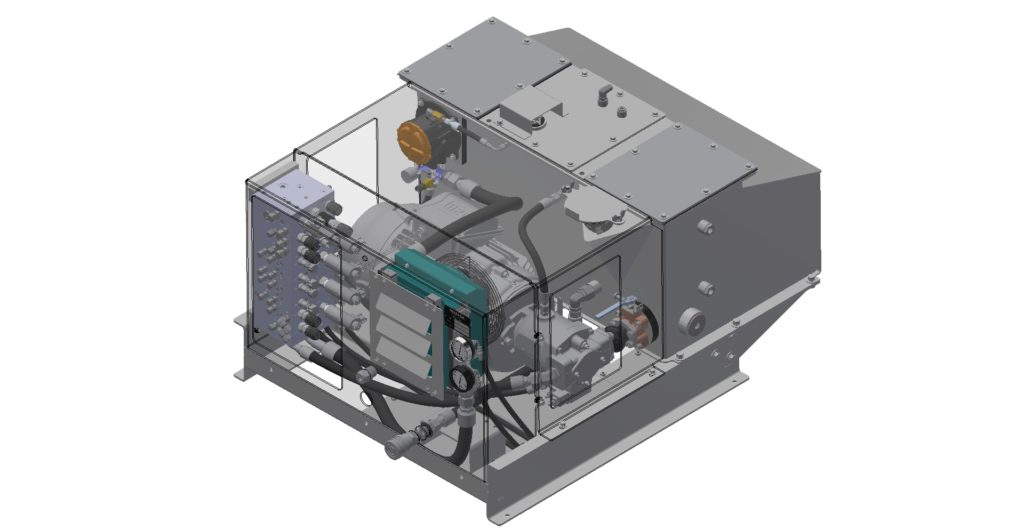

Fabrication & Assembly of Hydraulic Power Unit Systems:

- Prime mover options:

- Gas engines

- Diesel engines

- Hydraulic Integrated Circuits (HICs)

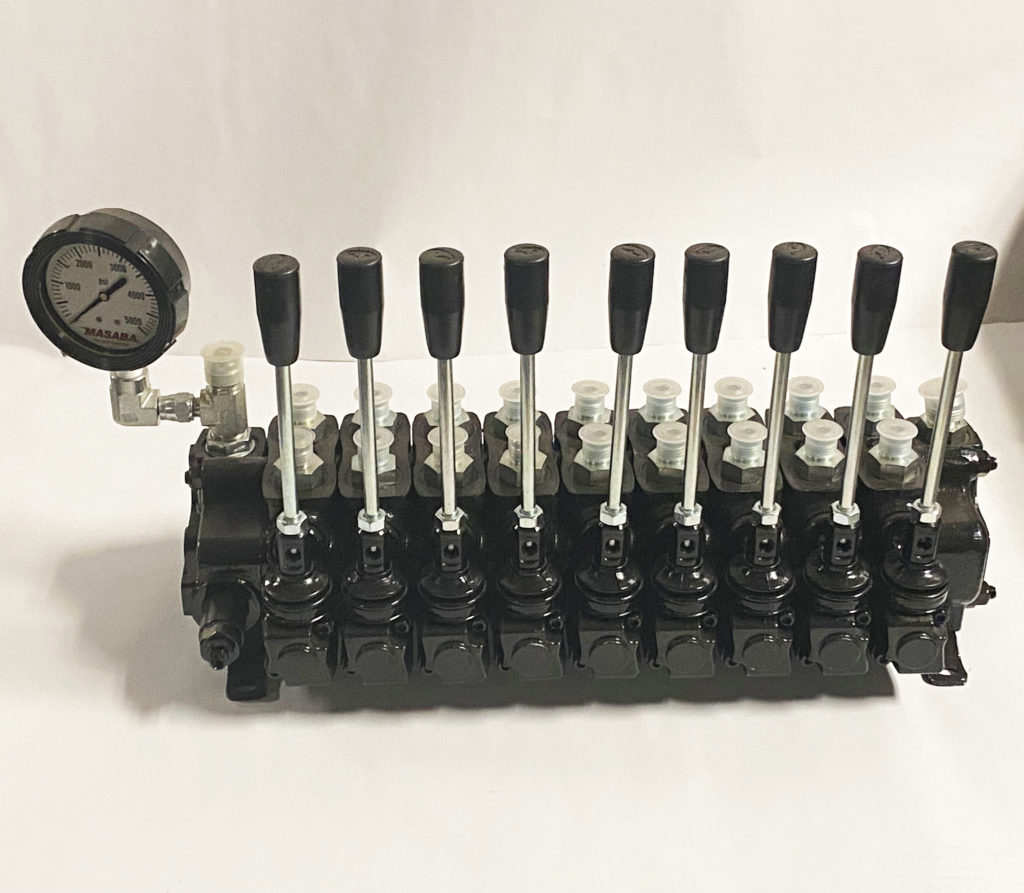

- Industrial and mobile valve assemblies

- Electric motor — AC/DC operation

- Hose assembly, labeling, and kitting

Testing Capabilities:

- 30 HP VFD-controlled 3.00 cubic in/rev, 4500 PSI load sense piston pump

- 30 HP VD-controlled for auxiliary testing of assembled systems

- 5000 PSI, 32 GPM, proportionally controlled five-station load-testing manifold

- HMI control for manual and automated testing and display pressures flows:

- 12-volt DC controls: (12) proportional — 6 off/on outputs

- 24-volt DC controls: (22) proportional — 18 off/on outputs

- 115-volt AC controls: (9) off/on outputs

- Contamination monitoring of particulates and water

- Manifolds to test and set many industry-standard cartridge valves

What We Offer and Stock

- Pumps

- Cylinders

- Hydraulic Power Units

- Filters & Elements

- Hose Assemblies

- Motors

- Valves

- HIC Manifolds

- Gauges & Sensors

- Fittings

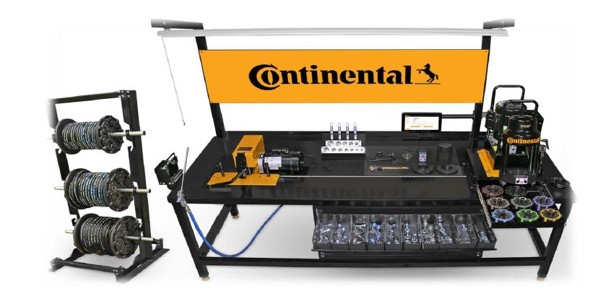

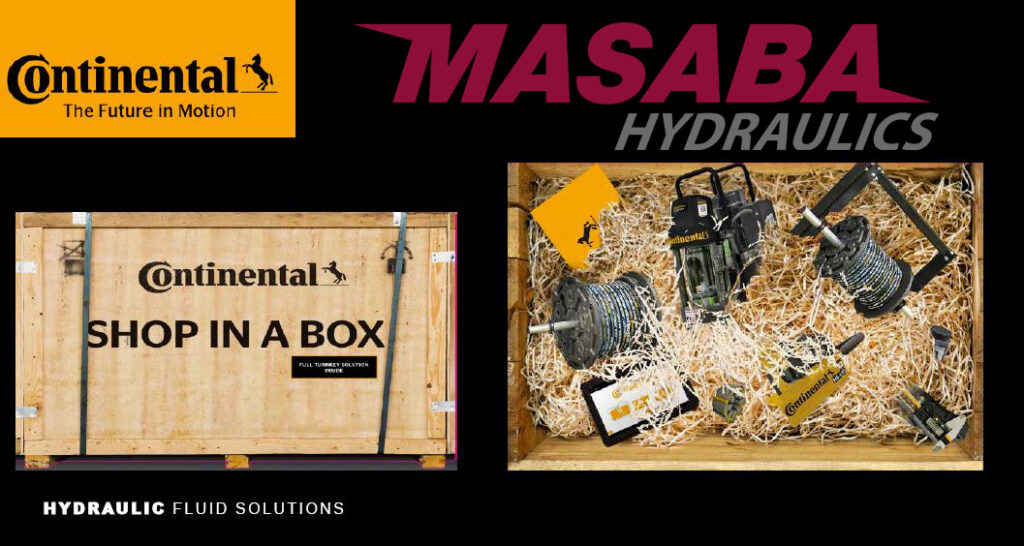

Create a hydraulic and industrial hose shop right in your current location with Continental’s Shop-in-a-Box. This turnkey setup contains a crimper and all the accessories you need to produce premium Continental assemblies. With four available options to meet your needs, this new assembly solution is ready to perform.